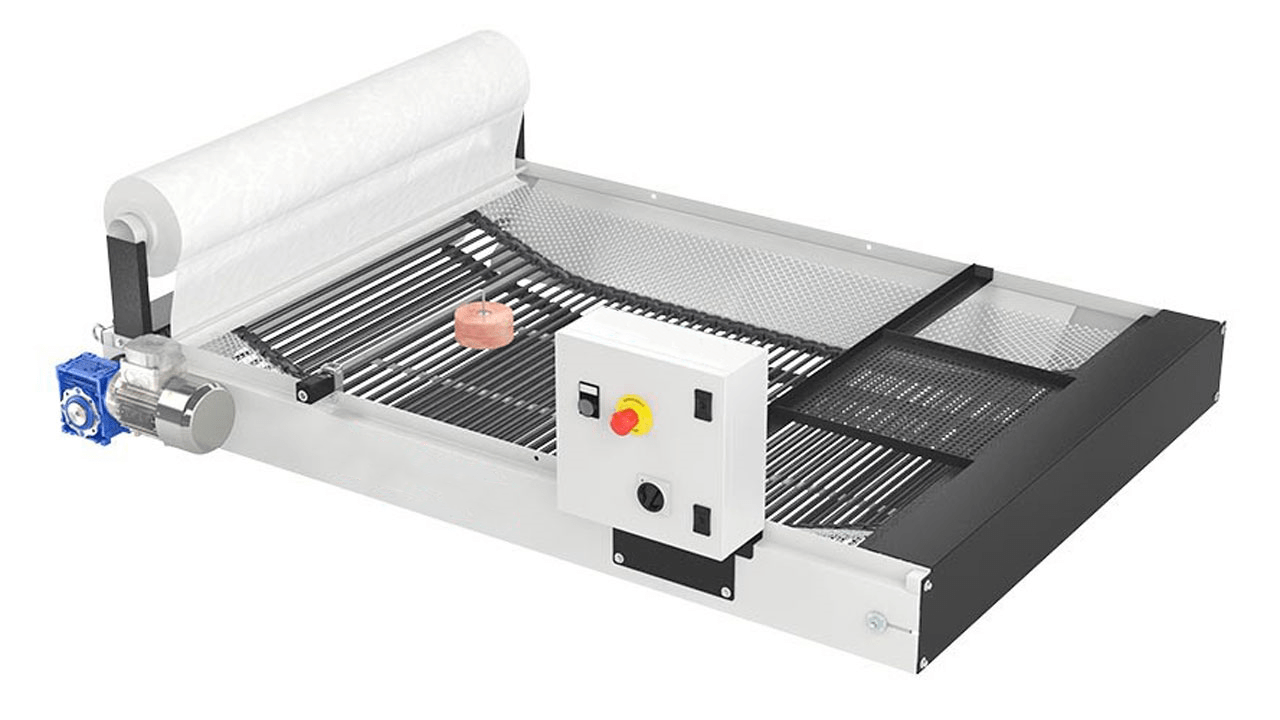

Flatbed Filtration Systems

Flatbed Filtration Systems

In addition to providing nonwoven filters to suit your particular application, we also have the technical scope to offer complete flatbed filtration systems to complement your chosen filter media. Extending the life of coolant, mineral oils and hot frying oils, reducing maintenance costs and increasing service intervals are all the benefits of using flatbed filtration systems.

The oil is dispersed onto the filter media and passes through the filter which collects any fry debris. A solid cake builds up on the filter paper and the flow of oil eventually reduces, resulting in the oil level rising. This in turn activates a float switch which indexes the filter paper and provides a new clean layer of filter media. The clean fry oil is pumped back to the frying process and the contaminated filter paper is deposited in a bin at the end of the flatbed system.

We offer a full range of flatbed filter systems starting at 300mm width up to 1400mm. Flow ranges from 15 to 275 l/min dependent on the viscosity of the oil. The degree of filtration can be selected by increasing the weight of media typically ranging from 10 to 50 micron. Available in 7 models, the flatbed unit utilises the following roll widths*:

- 400 mm

- 500 mm

- 700 mm

- 1000 mm

- 1400 mm

* Model selected will be dependent on widths.

Please contact us regarding the models available and we will tailor the system to suit your application.

Power Utilities Limited,

Queen Street,

Premier Business Park,

Walsall, WS2 9QE

+44(0)1922 668 374

FILTRATION MEDIA

FOLLOW US